Maximizing Examining Accuracy With Secured Examination Units in Electronic Development Processes

In the realm of electronic advancement processes, the mission for precision and dependability in screening techniques remains critical. Protected examination rooms have become a key tool in boosting the precision of screening treatments for electronic components and devices. These enclosures function as a safety obstacle against external disturbance, making certain a regulated screening atmosphere. The use of protected test enclosures expands beyond mere insulation, offering a myriad of advantages that add to the overall top quality and performance of testing outcomes. By discovering the subtleties of secured units and their influence on screening precision, a deeper understanding of their significance in digital advancement processes is introduced.

Significance of Shielded Test Units

The use of shielded test rooms is paramount in ensuring reputable and accurate electronic advancement procedures. Secured units offer a regulated screening environment by avoiding electro-magnetic disturbance (EMI) from exterior sources that could jeopardize the honesty of digital testing procedures. This is especially vital in delicate electronic measurements where even the least disturbance can result in incorrect outcomes. By consisting of the electro-magnetic signals within the unit, secured test rooms assist preserve the uniformity and repeatability of examination outcomes, ultimately boosting the total quality of electronic development procedures.

In addition, secured examination rooms add to meeting regulatory standards and conformity demands in the electronics industry. These units assist in creating a shielded space that decreases the danger of exhausts that might conflict with various other electronic tools or interaction systems. This not just ensures the reliability of the tools being checked however also prevents any kind of prospective disturbances to bordering equipment. Basically, the significance of secured test units lies in their capacity to guard the accuracy and dependability of electronic advancement procedures with the creation of an interference-free and regulated screening environment.

Kinds Of Secured Test Rooms

Different setups of protected test enclosures provide to varied testing needs and specs in electronic development procedures. Furthermore, mobile protected test enclosures use versatility for on-site screening or when flexibility is needed. Overall, the option of protected test room depends on the particular screening requirements, the size of the gadgets being tested, and the level of movement required in the electronic growth process.

Benefits of Making Use Of Shielded Rooms

Enhancing electro-magnetic compatibility and making sure trusted examination outcomes, secured units play an essential duty in keeping the honesty of digital development procedures. Among the vital advantages of using protected units is their capability to alleviate electro-magnetic disturbance (EMI) from exterior sources. By offering a controlled atmosphere with marginal outside interference, secured enclosures enable accurate screening of digital devices without the risk of incorrect outcomes brought on by undesirable electro-magnetic signals.

Additionally, protected rooms use a high degree of protection by stopping delicate details from dripping out and unauthorized signals from entering the testing setting. This function is especially important when testing proprietary or confidential digital elements that need a protected testing environment.

In addition, shielded rooms help in abiding by regulatory criteria and accreditations by providing a regulated screening atmosphere that meets the needed electro-magnetic compatibility (EMC) guidelines. This guarantees that the electronic gadgets being examined will satisfy the necessary market criteria for electromagnetic exhausts and immunity, causing smoother accreditation procedures and quicker time-to-market for products.

Considerations for Protected Unit Option

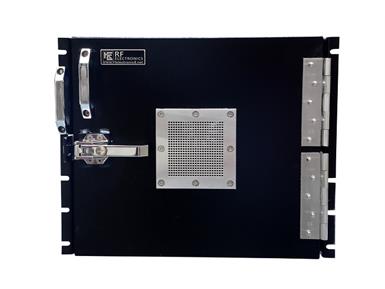

In the procedure of choosing secured enclosures for electronic advancement, mindful consideration of certain needs and ecological elements is vital. When selecting a shielded room is the product made use of for its building and construction, the first factor to consider. Conductive products such as steel or aluminum are typically favored for their securing performance. Additionally, the size of the unit must be sufficient to fit the digital components being checked while permitting for correct air flow and cable television monitoring.

One more important factor to take into consideration is the degree of securing needed for the screening environment. High-frequency applications might require units with remarkable electromagnetic disturbance (EMI) securing capacities to protect against signal disturbance and make sure precise test outcomes. In addition, the availability functions of the enclosure, such as panels, ports, and doors, should straighten with the testing demands to help with hassle-free access to the tools under examination.

Last but not least, the mobility and scalability of the shielded unit should be examined to ensure adaptability in fitting future screening needs and prospective reconfigurations. By thoroughly assessing these factors to consider, digital development processes can take full advantage of testing accuracy and performance with the appropriate secured enclosure selection.

Integration of Shielded Enclosures in Testing

The seamless integration of protected rooms into testing treatments is vital for guaranteeing precise and useful content reputable electronic growth processes. Protected rooms play a crucial role in minimizing external disturbance throughout try these out screening, consequently improving the accuracy of outcomes. When incorporating shielded enclosures right into testing settings, it is essential to consider factors such as the dimension of the unit, the kind of securing product utilized, and the certain screening demands of the electronic parts being reviewed.

One trick facet of incorporating shielded units right into screening is making certain appropriate connectivity within the unit. This consists of developing protected connections for source of power, information transfer, and surveillance devices to efficiently conduct examinations while preserving the shielding performance of the room. Additionally, applying proper ventilation and cooling down systems within the enclosure is crucial to avoid getting too hot of digital parts during testing procedures.

Verdict

In final thought, making use of secured examination enclosures in digital development procedures is essential for taking full advantage of testing accuracy. Various kinds of secured rooms offer different benefits, and careful consideration needs to be given to choosing one of the most suitable one for specific testing requirements. Incorporating shielded enclosures into the screening procedure can dramatically boost the integrity and effectiveness of electronic testing treatments.

Protected units provide a controlled screening environment by protecting against electromagnetic interference (EMI) from outside resources that might endanger the stability of digital screening treatments - rf test enclosure rochester. By containing the electromagnetic signals within the room, secured test rooms assist preserve the uniformity and repeatability of examination results, inevitably boosting the overall quality of electronic advancement processes

When incorporating secured units into testing atmospheres, it is crucial to consider factors such as the size of the room, the type of shielding material made use of, and the particular testing requirements of the electronic parts being assessed.

One secret element of integrating shielded units right into screening is making certain correct connection within the faraday cage rochester enclosure. Integrating shielded enclosures right into the screening process can considerably improve the integrity and effectiveness of electronic screening procedures.

Comments on “Ultimate Faraday Cage Rochester: Secure Your Electronic Devices from RF Disturbance”